100w

No downtime or extended lead times: By combining a tube mill and tube laser in a single facility, we can move your project through each stage with no gaps or delays. We are a full line service center that will:

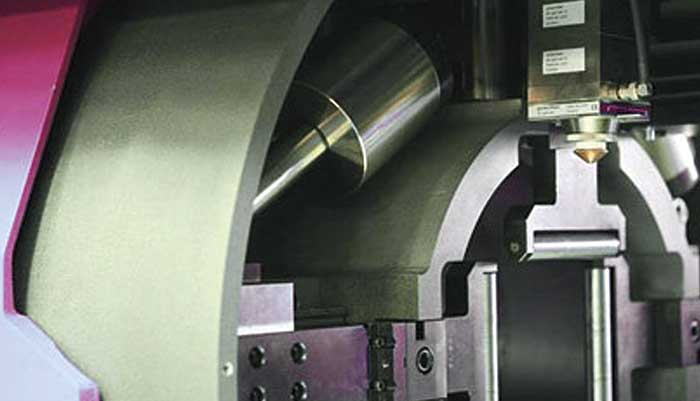

ExactCut 430 laser cutting machine is a precise laser cutting system that automates the processing of thin and heavy metals, alloys, brittle materials such as sapphire, PCD and ceramics.